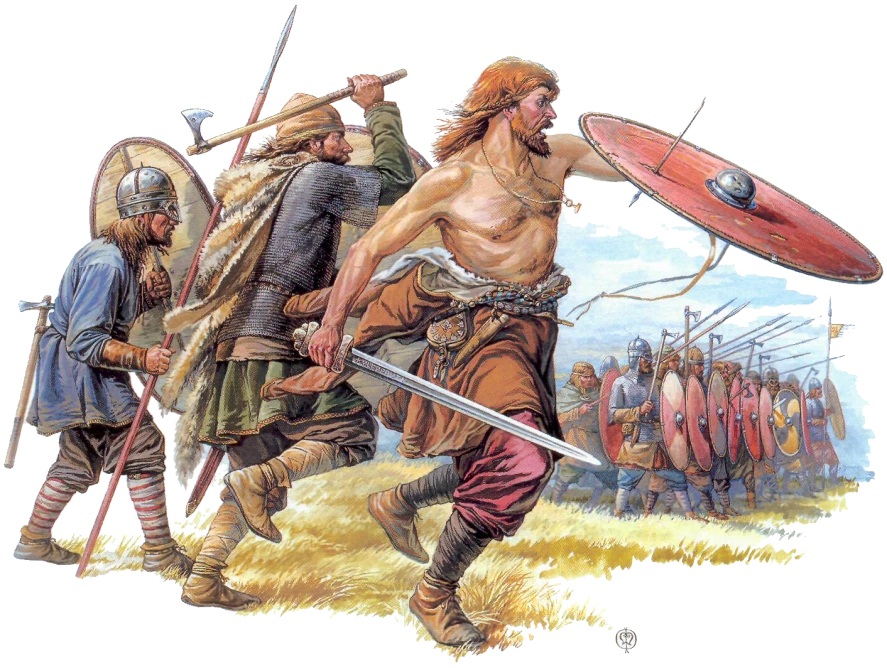

Battle-ready shields

Contents

Battle ready shields

Construction and materials

The high durableness of the shields consists in their construction and in materials they are made of. The base board consists of three 3 mm thick beech veneered boards. The beech wood is an optimal material, as it is quite light and very firm. The front of the shield is coated in two layers of tent canvas (100% cotton, 300-500 g / m2). The fabric increases the shield stability and dampens the blows falling onto the shield.

The rear side is covered with a thinner canvas (200 - 300 g / m2) to maintain the historical appearance, as plywood is not a historically authentic material. Moreover, the fabric cover prevents accidental tearing of a splitter. The outer edge of the shield is hemmed with rawhide (also called parchment) that prevents splitting the plywood edge. The rawhide is sewn to the veneer boards with a rawhide cord.

The wooden handles and leather straps are riveted with iron rivets to the wooden boards. The rivets are annealed, so you can hammer their ends flat easily. Compared to steel armor, the rivet ends are not so much hammered flat. These rivets joints are strong enough and can be easily unrivetted when a leather strap or wooden rib needs replacing.

Your protection behind the shield

The opponents' strikes generate on the shield an impressive texture over the time, what enhances the appearance and is to honor of its bearer. Apart from extreme situations, such as stabbing a sharp spearhead or steel hammer, you can rely on its protection.

Holding the shield

Most shield are held by the cross from two leather straps (Approx. 4mm thick and Approx. 20 mm wide). The shield is fixed to the forearm with a strong strap (Approx. 6 mm thick and 35mm wide Ca). Round Viking shields are held with one hand in the middle by the handle on the wooden rib. The hand is protected with the steel umbo from the outside.

Shields and humidity

The weather is unpredictable and battles take place in the open air, and therefore these shields are made of materials that can withstand bad weather. If your shield gets drenched in the rain, let it dry slowly, not in direct sunlight or at a radiator or by the oven. Let it stand on a well ventilated place in the shade where fresh air can access to both sides of the shield. If the shield is dried too quickly, its seams of untreated rawhide get curved.

Never leave the shield stand leaned against the tent in the sun. The rawhide absorbs in the nighttime moisture and when it gets in direct sunlight during the day, it dries and contracts quickly, which results in a strong tension.

Colors and paintings

The shields come one-colored in their standars versions. You can choose from the following colors: brown, black, green, blue, red, natural linen and rawhide. Upon request, an eblem or coat of arms can be painted on a shiled front. After we receive a graphic of sufficient resolution we can estimate the extra costs. The price of the painting depends on the size, color and complexity and is always calculated individually. Feel free to paint on the rawhide, but avoid synthetic and alcohol containing paints.

Whole cover with rawhide

The covering both sides of the shield gives the shield a higher mechanical resistance; on the other hand the total weight of the shield increases. That is why most buyers do not have their heater shields covered with rawhide.

Comments